DVM - Design Verification Module

|

The purpose of the StepLoad() test is to verify that the output voltage is within regulation when the load current is ramped between the initial and final current values. The input is configured as a DC Input Source, and the output is configured as a Ramp Load. The initial current is modeled as resistive and the actual load step is implemented with a current source. The initial and final current values are passed as arguments to the StepLoad() function in the testplan. The built-in testplans support both a load step increase and a load step decrease.

Both a POP and transient analysis are used in the StepLoad() test.

The test report includes source and load graphs as well as the following scalar values which are defined in the Measured Scalar Values section below:

In this Topic Hide

The StepLoad() function has the following syntax with the arguments described in the table below:

StepLoad(REF, ISTART, IFINAL)

StepLoad(REF, ISTART, IFINAL,

OPTIONAL_PARAMETER_STRING)

| Argument | Range | Description |

| REF | n/a | The actual reference designator of the DVM Load or the generic syntax of OUTPUT:n where n is an integer indicating a position in the list of managed DVM loads. |

| ISTART | min:0 | The starting current for the load. This can be a numeric value or a symbolic value, such as a percentage of full load. |

| IFINAL | min:0 | The final current for the load. This can be a numeric value or a symbolic value, such as a percentage of full load. |

| OPTIONAL_PARAMETER_STRING | n/a | Parameter string with a combination of one

or more timing parameters:

|

* If more than one parameter is specified, join the parameter key-value pairs with a space, as shown in the optional parameter string section below.

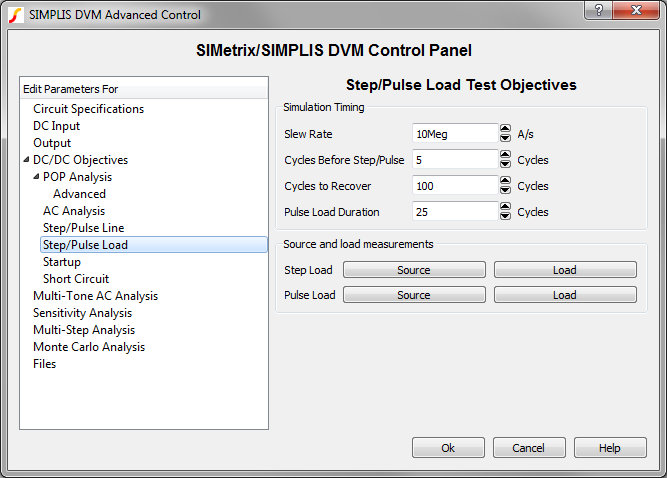

DVM sets the timing parameters for the StepLoad() test objective based on values that you enter on the following two tabs in the DVM Full Power Assist control symbol:

The time delay, rise time, and the simulation stop time are determined by these calculations:

\[ \text{TIME_DELAY} = \frac{\text{CYCLES_BEFORE_EVENT}}{\text{SWITCHING_FREQUENCY}} \]

\[ \text{RISE_TIME} = \frac{ abs \left( I_{FINAL}-I_{START} \right)}{\text{SLEW_RATE}} \]

\[ \text{STOP_TIME} = \text{TIME_DELAY} + \text{RISE_TIME} + \frac{\text{CYCLES_TO_RECOVER}}{\text{SWITCHING_FREQUENCY}}\]

Note: The switching frequency and cycles to recover parameters are not the actual measured values from a simulation; they are constant values taken from the DVM control symbol. Also, you can override time delay, rise time, and cycles to recover on a test-by-test basis by using the optional parameter string.

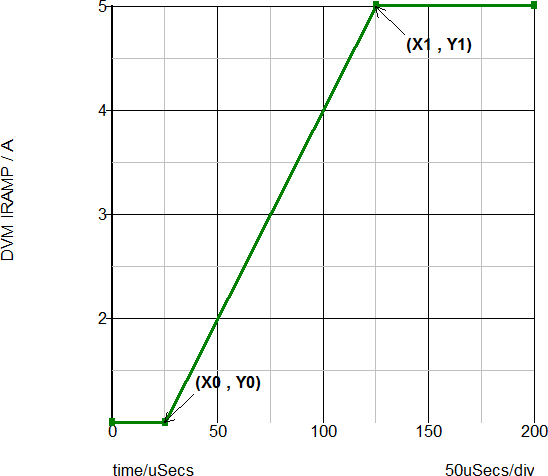

The output current ramp/step timing is annotated on the graph below:

| Annotation | Value |

| X0 | TIME_DELAY |

| X1 | TIME_DELAY + RISE_TIME |

| Y0 | ISTART (see note below) |

| Y1 | IFINAL (see note below) |

Note: The actual load current depends on the LOAD_RESISTANCE parameter and the actual time-varying load voltage. The ISTART current is modeled by a resistor defined by the LOAD_RESISTANCE parameter in the ramp load subcircuit. The PWL current source has points defined by the ramp-load START_CURRENT and FINAL_CURRENT parameter values.

The StepLoad() test objective sets the source and load subcircuits to the following:

| Source | Load |

| DC Input Source | Ramp Load |

Loads other than the output under test are set to the Resistive Load. All other sources are set to the DC Input Source.

The StepLoad() test objective measures the following scalar values,where {load_name} and {src_name} are replaced by the actual load name source name:

| Scalar Name | Description | ||||||||||||

| sw_freq | A number which represents the converter switching frequency. This scalar is generated from a fixed probe with curve label DVM Frequency. For more information, see Measuring the Switching Frequency. | ||||||||||||

| vout{n}_recovery_time | The number {n}

in the scalar name is an integer indicating a position in the

list of managed DVM loads.

The three possible return values are the following:

|

||||||||||||

|

The Average, Minimum, Maximum, RMS and Peak-to-Peak values for each load voltage and current taken over the entire simulation time window. | ||||||||||||

|

The Average, Minimum, Maximum, RMS and Peak-to-Peak values for each source voltage and current taken over the entire simulation time window. |

In the following table, {load_name} is the name assigned to each load. The default value is LOAD. DVM forces each load name to be unique so that the scalar and specification values for each load are unique.

| Specification Name | PASS/FAIL Criteria |

| Min_V{load_name} | The minimum value of the output voltage during the simulation time is greater that the minimum specification value. |

| Max_V{load_name} | The maximum value of the output during the simulation time is less than the maximum specification value. |

| Overshoot_V{load_name} | The maximum value of the output during the simulation time is less than the maximum overshoot specification value. |

| Undershoot_V{load_name} | The minimum value of the output during the simulation time is greater than the minimum undershoot specification value. |

The StepLoad() test objective is used in several built-in testplans. Shown below is a test from the DC/DC 1 input/1 output testplan. This test configures the load to step from the 50% full load value to the 100% full load value. The full load value is defined on the Output page of the Full Power Assist DVM control symbol.

| *?@ Analysis | Objective | Source | Load | Label |

| Transient | StepLoad(OUTPUT:1, 50%, 100%) | Source(INPUT:1, Nominal) | Transient|Step Load|Vin Nominal|50% Load to 100% Load |

The following StepLoad() test objective uses the OPTIONAL_PARAMETER_STRING argument to set the output load to step between the Light and 100% symbolic values and sets the ramp time delay to 25us and the ramp rise time to 100us.

StepLoad(OUTPUT:1, 50%, 100%, TIME_DELAY=25u RISE_TIME=100u)

You can view the complete test report in a new browser window here: StepLoad() Test Report. Below is an interactive link to the same test report.

© 2015 simplistechnologies.com | All Rights Reserved