The Full Power Assist DVM control symbol stores the same information

as the Basic DVM control symbol but

also includes specifications for the sources and loads, as well as performance

specifications. The DVM control symbol dialog consists of two areas:

- The page selection box on the left where you select the page that

you want to edit

- The entry fields on the right side of the dialog where you enter

specifications

Adding a Full Power

Assist DVM Symbol to a Schematic

To add a Full Power Assist DVM Control

Symbol to a working schematic, follow these steps:

- From the parts selector, choose DVM ▶ Control Symbols ▶ Full Power Assist DVM

Control Symbol.

Result: The SIMPLIS DVM Power

Assist Control Symbol appears.

- Place the symbol at the top of the schematic.

- Double click the symbol.

Result: The SIMPLIS DVM

Control Panel dialog opens for you to enter the information that is described in

the following sections.

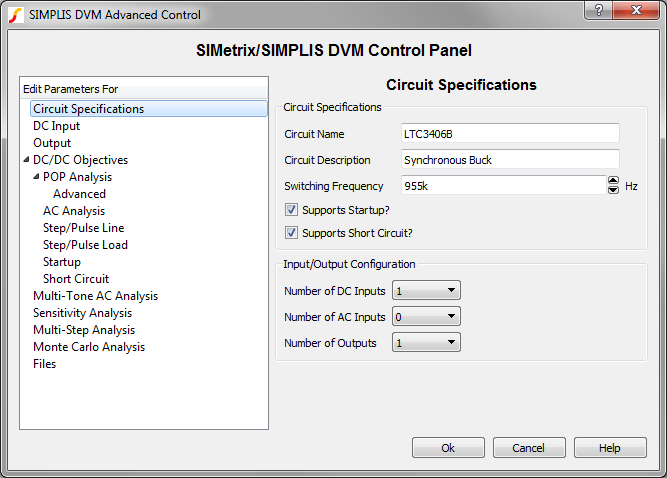

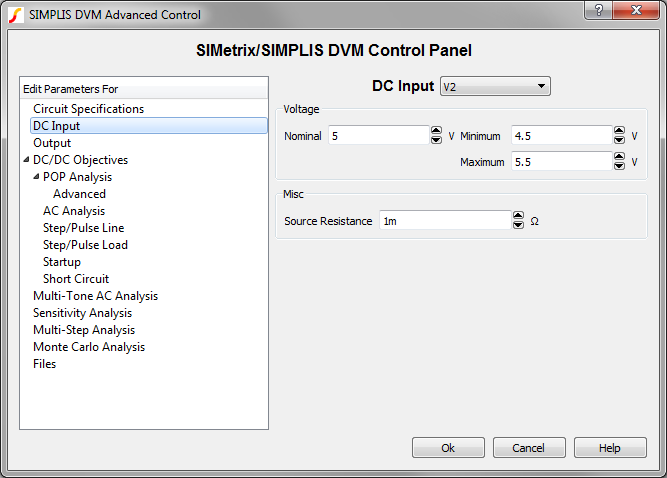

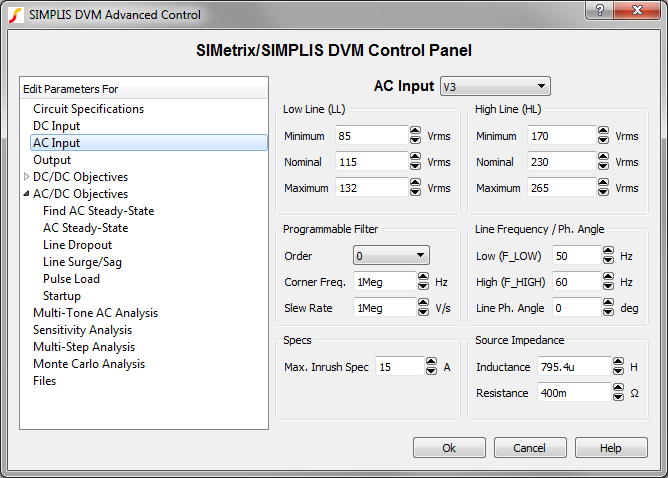

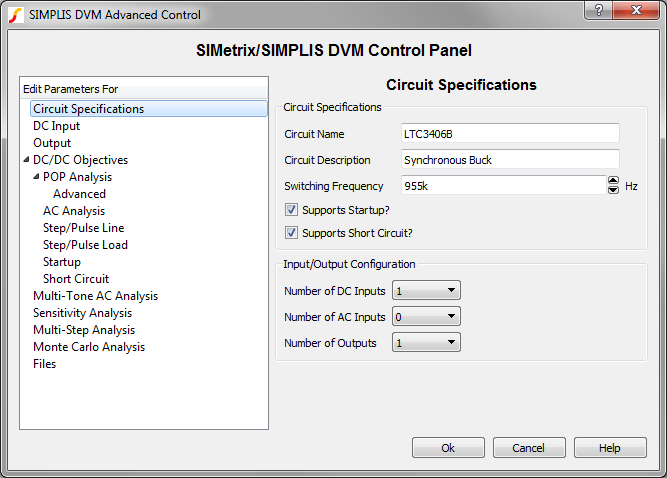

Circuit Specifications

The Circuit Specifications page allows you to

define circuit descriptions and specifications that DVM uses when measuring and checking

scalar values in the simulation. On this dialog, you also specify the number of DC inputs,

AC inputs, and outputs. Additional pages appear for each input and for each output as shown

in the page selection panel below. This dialog is configured for one DC input and one output

load.

| Label |

Parameter Description |

| Circuit Name |

Name of the circuit as it will appear

in the DVM report; for display purposes only. |

| Circuit Description |

Description of the circuit under test

which appears in the DVM Control symbol; for display purposes only. |

| Switching Frequency |

Nominal switching frequency used to

calculate simulation timing for DC/DC test objectives |

| Supports Startup? |

If checked, the Startup() test

objectives startup tests will be performed; if not checked, the Startup() test

objectives will be skipped. |

| Supports Short Circuit? |

If checked, the ShortCkt() test

objectives will be performed; if not checked, theShortCkt() test objectives will be

skipped. |

| Number of DC Inputs |

The numbers that you select in these

three fields dynamically change the page selection list to accommodate the number of

AC and DC inputs and the outputs that will then be available for you to

configure. |

| Number of AC Inputs |

| Number of Outputs |

▲ back to top

▲ back to top

▲ back to top

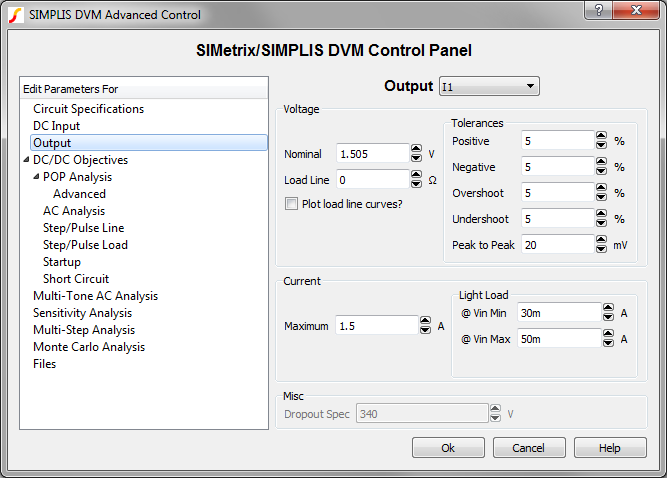

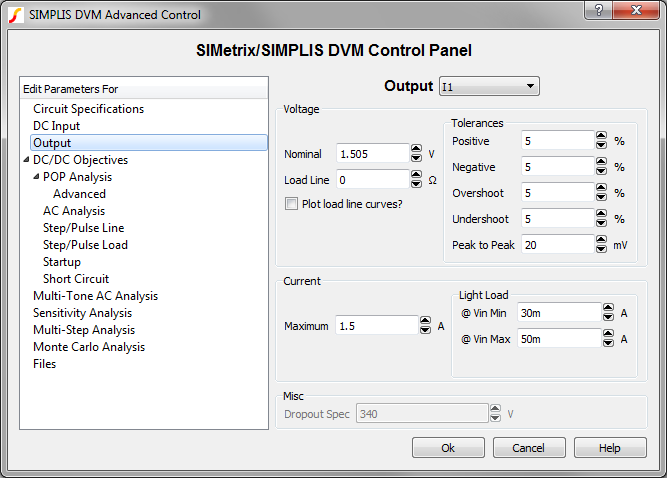

Output Page

An Output page is added for each load

that was defined on the Circuit

Specifications page. The Output page allows you to define specifications

for each output source in your circuit. The Output drop-down menu at the top allows

you to select the reference designator from a list of available DVM Loads. For a list

of available output load subcircuits, see Output Load

Subcircuits.

Note: DVM supports up to five outputs.

To increase or decrease the number of

managed outputs, change that number on the Circuit Specifications page before you edit the DVM control symbol to add

a new load.

To place a new load

on the schematic and then manage the output, follow these steps:

- From the Output drop-down menu, select Place New Load, and then click

Ok.

Result: A dialog opens, prompting you

to place the new source.

- Click Ok and then click to place the load on the schematic.

Note: If you

click Cancel at any point when you are placing sources and loads, all

previous actions will be cancelled and you must re-edit the control symbol and

place all the sources and loads again; or you can manually place the sources

and loads before you edit the control symbol and then select them from the

drop-down menus.

| Voltage: Specifications for

output voltage |

| Nominal |

Nominal DC output

voltage |

| Load Line |

The nominal output

impedance of the output. This is used in conjunction with the nominal

voltage to determine if the output voltage is within the setpoint range

and overshoot/undershoot specifications. The formula for the output

voltage setpoint, overshoot, and undershoot are shown below:

\[ \text{Positive Setpoint Limit} =

\text{Nominal} * 1 + \frac{\text{Positive}}{100} - \text{Load Line} *

\text{ILoad} \] \[ \text{Negative Setpoint Limit} = \text{Nominal} * 1 -

\frac{\text{Negative}}{100} - \text{Load Line} * \text{ILoad} \] \[

\text{Overshoot Limit} = \text{Nominal} * 1 +

\frac{\text{Overshoot}}{100} - \text{Load Line} * \text{ILoad} \] \[

\text{Undershoot Limit} = \text{Nominal} * 1 -

\frac{\text{Undershoot}}{100} - \text{Load Line} * \text{ILoad}

\] |

| Plot load line

curves? |

If checked, curves

representing the minimum and maximum output voltage specification will be

added to the output voltage graph. |

| Tolerances: Specifications

for output voltage tolerances |

| Positive |

Maximum positive percentage

tolerance for the output voltage setpoint |

| Negative |

Maximum negative percentage

tolerance for the output voltage setpoint |

| Overshoot |

Maximum percentage

tolerance for the output voltage overshoot |

| Undershoot |

Maximum percentage

tolerance for the output voltage undershoot |

| Peak to Peak |

Maximum allowed

peak-to-peak voltage at the output |

| Current: Specifications for

output current |

| Maximum |

Maximum output current at

100% load |

This parameter is a Symbolic Value

which can be used in a testplan. |

| Light Load: Specifications

for minimum output current |

| @ Input 1 min |

Light load specification

where POP analysis will succeed when Input 1 is at its minimum

voltage |

These parameters are Symbolic Values

which can be used in a testplan. |

| @ Input 2 max |

Light load specification

where POP analysis will succeed when Input 1 is at its maximum

voltage |

| Misc: Appears only when you

have an AC Input |

| Dropout Spec |

Minimum output voltage

specification for Line

Dropout test objective. |

▲ back to top

DC/DC Objectives

The DC/DC objectives section has seven sub categories of parameters:

Although you can use the DC/DC objectives on an AC/DC converter, you should also see the

specialized . The DC/DC Objectives require at least one DC or AC input source and one

output load. You can add these to your design on the Circuit

Specifications page.

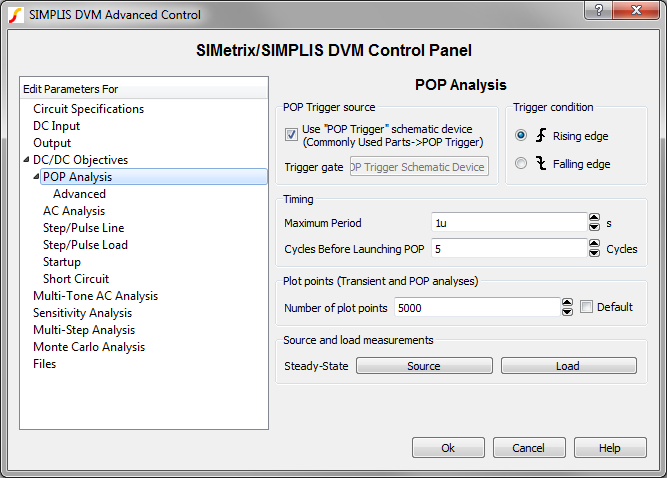

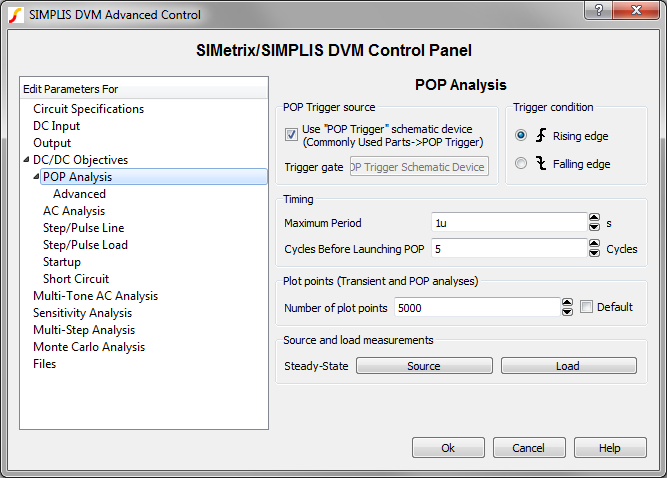

POP Analysis

The POP

Analysis page allows you to define parameters for the Periodic Operating Point

simulations used in the DC/DC test objectives. Each test objective, with the exception

of the Startup objective, uses a POP analysis to find

the steady-state operating point of the converter. When you first place a control

symbol, these analysis parameters are automatically read from the schematic and saved on

the control symbol. The DVM ▶Reset Analysis Parameters menu performs this action

as well.

Note: A successful POP run is a prerequisite for AC analyses and for all

DC/DC objectives except the Startup test objective.

| Simulation Parameters |

| POP Trigger Source |

Device name of a defined logic

gate considered the triggering gate of the POP analysis |

| Trigger Condition |

Trigger condition that defines

the beginning of a new switching cycle for the POP analysis |

| Maximum Period |

Defines the maximum period, or

lowest frequency, where POP looks for a steady-state solution |

| Cycles Before Launching

POP |

The number of POP trigger

events before starting the Core POP Process. |

| Number of plot points |

The number of points the

simulation uses. SIMPLIS automatically adds plot points when a PWL device

changes state or when a logic signal or switch changes state. |

For more information on the POP analysis, see the Advanced SIMPLIS Training

topic 2.3.1

Overview of the Periodic Operating Point (POP) Analysis.

▲ back to top

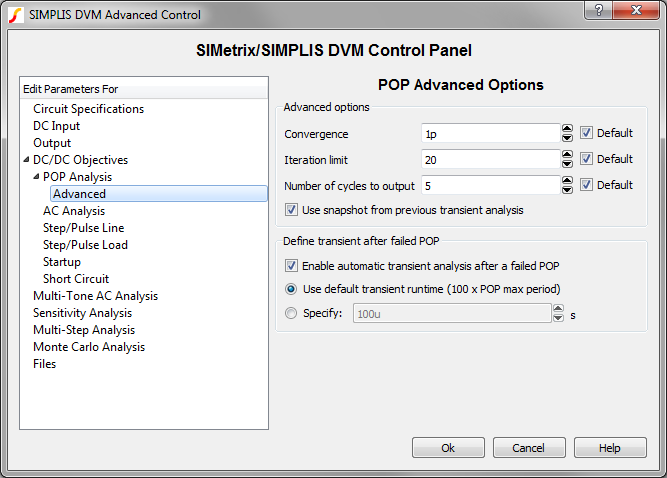

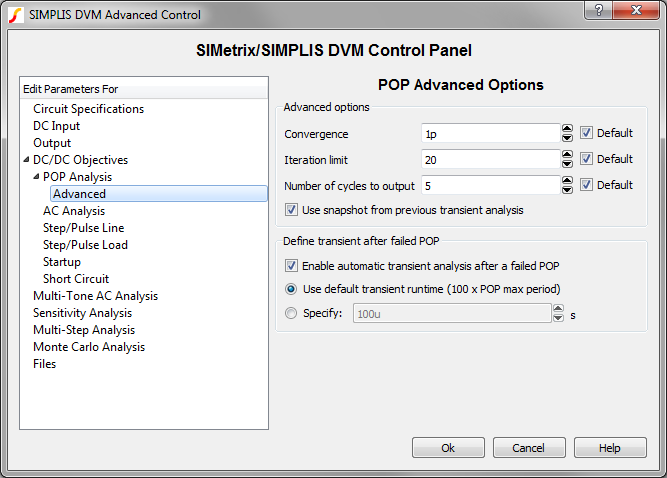

POP Advanced

Options

| Advanced Options |

| Convergence |

The maximum percent change

in any inductor current or capacitor voltage from one POP trigger edge to

the next |

| Iteration limit |

The maximum number of

passes through the core POP process |

| Number of cycles to

output |

The number of POP periods

to display on the waveform viewer |

| Use snapshot from previous

transient analysis |

If checked, a valid

snapshot will be loaded from a previous transient analysis. |

| Enable automatic transient

after a failed POP |

If checked, a transient

analysis will be run after a failed POP run. |

| Use default transient

runtime (100 x POP max period) |

If selected, the transient

analysis will run for 100 times the maximum POP period. |

| Specify |

If selected, the transient

analysis will run for the specified number of seconds. |

For more information on the advanced POP options, see the Advanced SIMPLIS

Training topic 2.3.2

The Core POP Process.

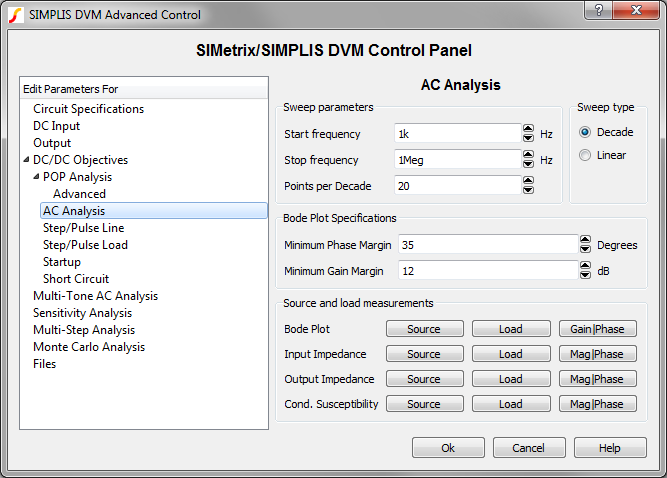

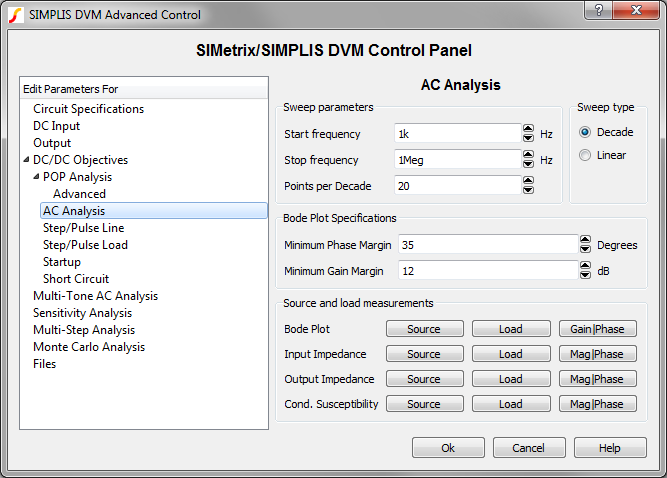

AC

Analysis

The AC Analysis page allows you to define simulation parameters for

the three AC test objectives:

| Simulation Timing:

BodePlot, Impedance and ConductedSusceptibility test objectives |

| Start Frequency |

Start frequency for AC

analyses |

| Stop Frequency |

Stop frequency for AC

analyses |

| Sweep Type |

AC sweep type: Decade or

Linear |

| Points per Decade |

Number of points per

decade, or the total number of points for a linear sweep. |

| Bode Plot

Specifications |

| Minimum Phase

Margin |

Minimum phase margin

specification for BodePlot test objective. |

| Minimum Gain Margin |

Minimum gain margin

specification for BodePlot test objective. |

| Source and load

measurements |

| Bode Plot |

The Source and Load buttons

allow you to select voltage and current measurements for each of these

test objectives. The Gain|Phase and Mag|Phase buttons allow you to select

magnitude and phase measurements. |

| Input Impedance |

| Output Impedance |

| Cond.

Susceptibility |

For more information on these parameters, see Chapter 11, SIMPLIS-FX, in the

SIMPLIS Reference

Manual

. If your circuit is pre-configured to run an AC analysis when you place the DVM

control symbol, these values will automatically be extracted from your

schematic.

▲ back to top

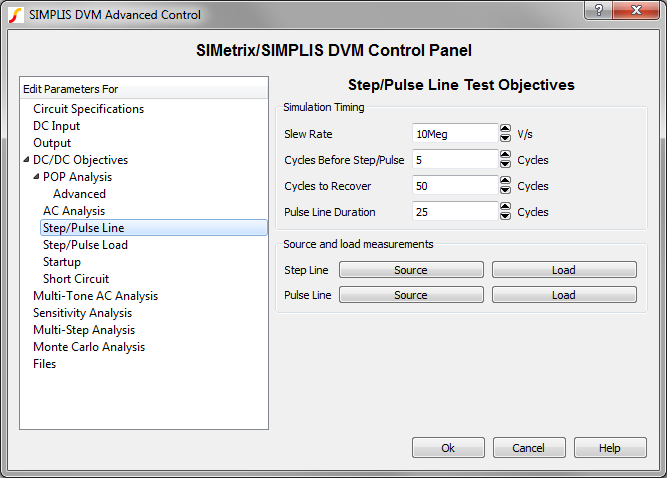

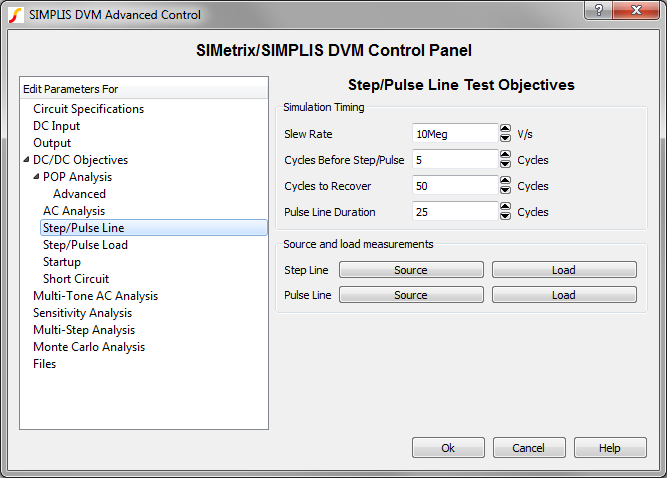

Step/Pulse

Line

The Step/Pulse Line Test Objectives page allows you to set the simulation

timing to use for the Step Line and Pulse Line test objectives.

| Simulation Timing |

| Slew Rate |

The slew rate of the line

voltage step or pulse in V/s |

| Cycles Before Event |

Combined with the nominal

switching frequency, this parameter determines the length of time before the

start of the line transient. |

| Cycles to Recover |

Combined with the nominal

switching frequency, this parameter determines the length of time that the

circuit has to recover after the end of the line transient. |

| Pulse Line Duration |

The time duration of the line

pulse expressed in the number of switching cycles |

▲ back to top

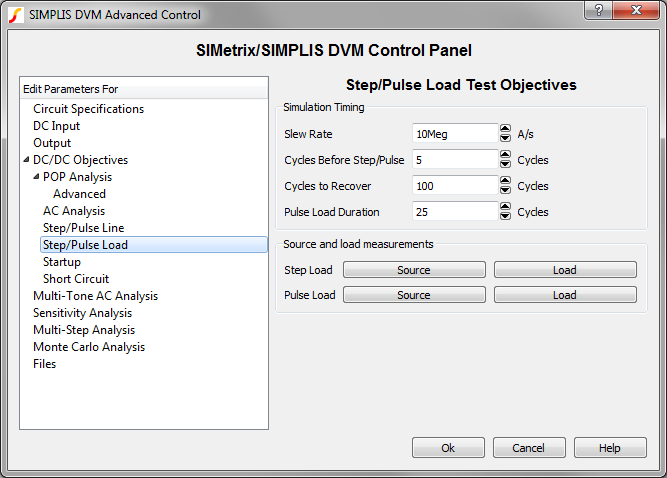

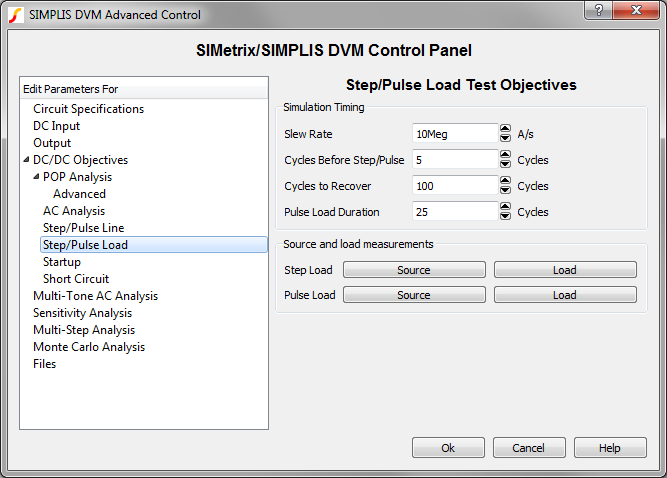

Step/Pulse

Load

The Step/Pulse Load Test Objectives page allows you to set the simulation

timing to use for the Step Load and Pulse Load test objectives.

| Simulation Timing |

| Slew Rate |

The slew rate of the load

current step or pulse in A/s |

| Cycles Before Event |

Combined with the nominal

switching frequency, this parameter determines the length of time before the

start of the load transient. |

| Cycles to Recover |

Combined with the nominal

switching frequency, this parameter determines the length of time that the

circuit has to recover after the end of the load transient. |

| Pulse Load Duration |

The time duration of the load

pulse expressed in the number of switching cycles |

| Source and load

measurements |

| Step Line |

The Source and Load buttons

allow you to select voltage and current measurements for each of these test

objectives. |

| Pulse Line |

▲ back to top

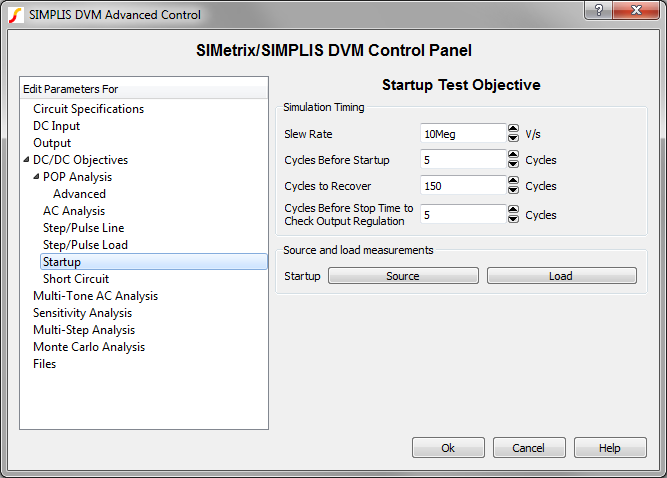

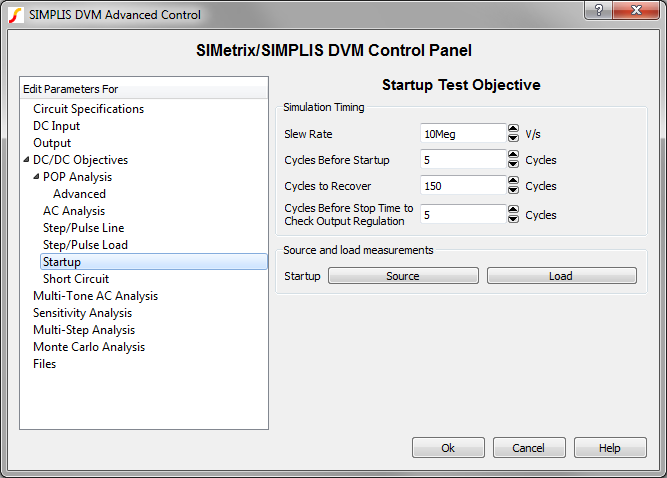

Startup

The

Startup Test Objective page allows you to set the simulation timing for the Startup Test Objective.

| Simulation Timing |

| Slew Rate |

The slew rate of the input

voltage source in V/s |

| Cycles Before Event |

Combined with the nominal

switching frequency, this parameter determines the length of time before the

start of the startup transient. |

| Cycles to Recover |

Combined with the nominal

switching frequency, this parameter determines the length of time that the

circuit has to recover after the end of the startup transient. |

| Cycles Before Stop Time to

Check Output Regulation |

Combined with the nominal

switching frequency, this parameter determines the length of time at the end

of the simulation in which the circuit is examined to determine that it is

in regulation. |

| Source and load

measurements |

| Startup |

The Source and Load buttons

allow you to select voltage and current measurements for this test

objective. |

▲ back to top

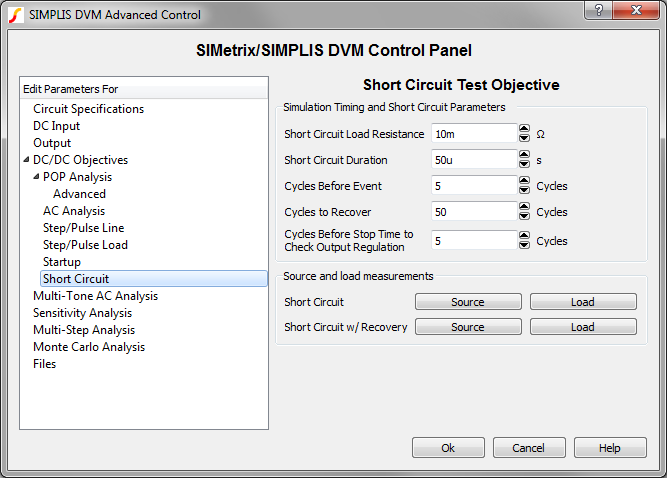

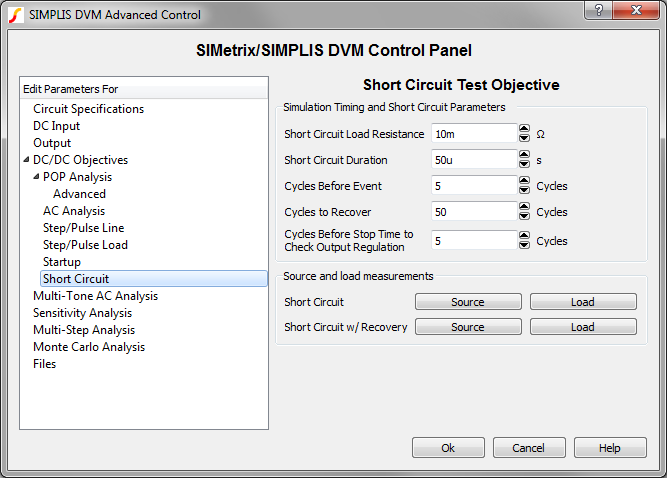

Short

Circuit

The Short Circuit Test Objective page allows you to set the simulation

timing and short circuit resistance parameters for the Short

Circuit test objective.

| Simulation Timing and Short

Circuit Parameters |

| Short Circuit Load

Resistance |

ON resistance of the switch

used to implement the short circuit |

| Short Circuit Duration |

Length of the short circuit

event in seconds |

| Cycles Before Event |

Combined with the nominal

switching frequency, this parameter determines the length of time before the

start of the short circuit. |

| Cycles to Recover |

Combined with the nominal

switching frequency, this parameter determines the length of time that the

circuit has to recover after the end of the short circuit. |

| Cycles Before Stop Time to

Check Output Regulation |

Combined with the nominal

switching frequency, this parameter determines the length of time at the end

of the simulation in which the circuit is examined to determine that it is

in regulation; applies only to Short Circuit and Recover tests. |

| Source and load

measurements |

| Short Circuit |

The Source and Load buttons

allow you to select voltage and current measurements for each of these test

objectives. |

| Short Circuit w/

Recovery |

▲ back to top

AC/DC Objectives

The AC/DC Objectives section has six sub categories of parameters:

The DC/DC Objectives can also be applied to AC/DC converters if the converter is

designed to perform a POP analysis.

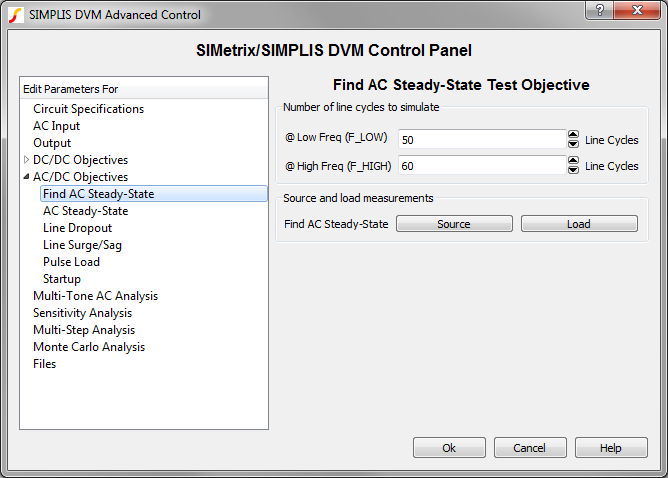

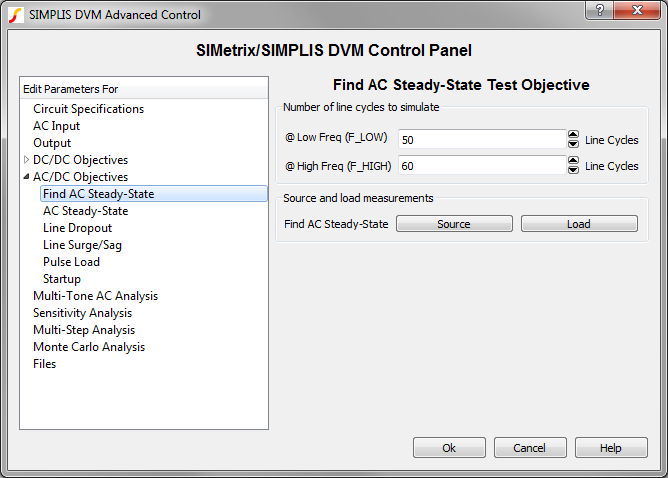

Find AC Steady-State

The Find

AC Steady-State Test Objective page allows you to define the simulation timing for

the FindACSteadyState Test Objective.

This test objective runs a long transient simulation and saves an initial-conditions

file with the GenerateInitFile testplan

entry. This initial-conditions file is then loaded into a future simulation to

initialize the converter to a steady-state condition. The timing parameters here

reference the F_LOW and F_HIGH symbolic

values which are defined on the AC

Input page.

| Number of line cycles to

simulate: Timing parameters that determine length of transient simulation

for the Find AC Steady-State test objective |

| @Low Freq (F_LOW) |

Number of line cycles to

simulate in order to find the steady-state operating point of the circuit

at the lower frequency. The default values result in a stop time of

1s. |

| @High Freq (F_HIGH) |

Number of line cycles to

simulate in order to find the steady-state operating point of the circuit

at the higher frequency. The default values result in a stop time of

1s. |

| Source and load

measurements |

| Find AC

Steady-State |

The Source and Load buttons

allow you to select voltage and current measurements for this test

objective. |

▲ back to top

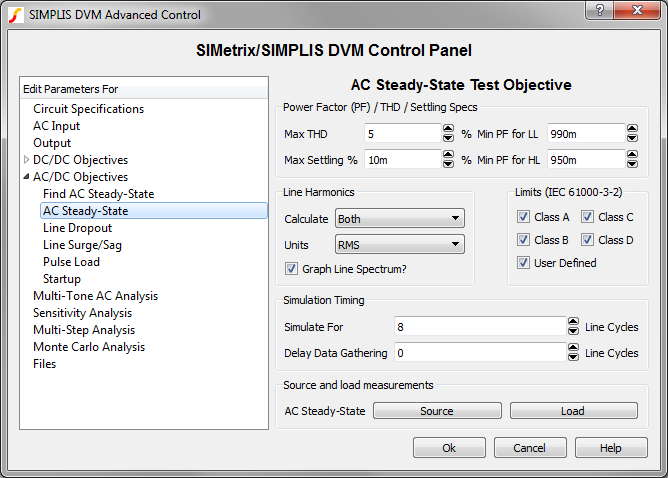

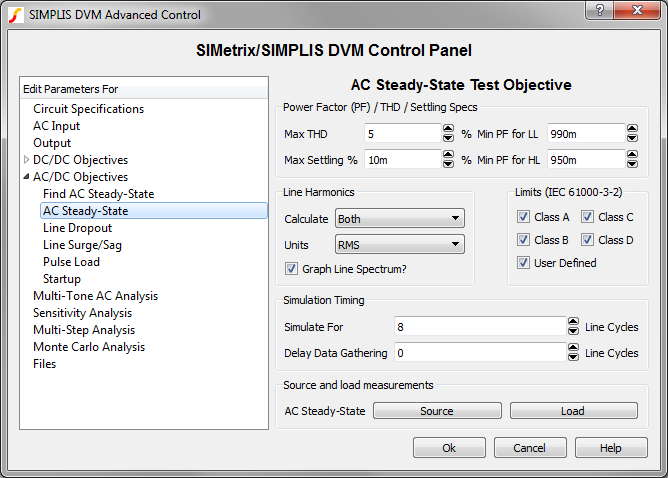

AC Steady-State

The AC Steady-State test objective measures

the performance of the converter under steady-state input voltage and output-load

conditions. The converter is typically initialized to a steady state with an IncludeInitFile testplan entry. This includes

an initial-conditions file from a FindAcSteadyState simulation. For additional details, see the AcSteadyState test objective topic.

| Power Factor (PF) / THD /

Settling Specs: Specifications for the AC steady-state analyses |

| Max THD |

Maximum total harmonic

distortion allowed for input source, specified as a percentage of the

fundamental |

| Max Settling |

Maximum percent difference

between the mean values of the output voltage over the last two lines

cycles |

| Min PF for LL |

Minimum power factor for

low-line tests |

| Min PF for HL |

Minimum power factor for

high-line tests |

| Line Harmonics: Options to

configure how line harmonics are presented in the DVM report |

| Calculate |

Select the line harmonics

for which you want to generate scalar values for the DVM report; the menu

options are None, Odd, Even, Both. |

| Units |

The units for the reported

line harmonic scalar values; the menu options are RMS, % Fundamental,

mA/W. |

| Graph Line

Spectrum? |

If checked, DVM will

generate a plot of the line harmonics for the AC input source.

- If any check boxes are selected in the Limits (IE 61000-3-2)

section, plots are generated in the units specific to those limits.

- If no limits are selected, a single line current spectrum graph

will be generated in the units selected from the Units drop-down

menu.

|

| Limits (IEC 61000-3-2):

Specifications for line harmonic current limits |

| Class A |

If checked, measured line

harmonic currents will be compared with IEC 61000-3-2 Class A harmonic

limits. |

| Class B |

If checked, measured line

harmonic currents will be compared with IEC 61000-3-2 Class B harmonic

limits. |

| Class C |

If checked, measured line

harmonic currents will be compared with IEC 61000-3-2 Class C harmonic

limits. |

| Class D |

If checked, measured line

harmonic currents will be compared with IEC 61000-3-2 Class D harmonic

limits. |

| User Defined |

If checked, measured line

harmonic currents will be compared with the user-specified limits. The

limits are defined in a simple plain text file. For a full description,

see the AC/DC Harmonic

Specifications. |

| Simulation Timing:

Parameters that determine the length of the simulation and when to start

collecting waveform data |

| Simulate For |

Number of lines cycles to

simulate after the Data Gathering Delay. In combination with the

line frequency, this determines the stop time of the simulation. |

| Delay Data

Gathering |

Number of line cycles

before data generation starts. Usually this can be set to zero if the

initial-conditions file is accurate |

| Source and load

measurements |

| AC Steady-State |

The Source and Load buttons

allow you to select voltage and current measurements for this test

objective. |

▲ back to top

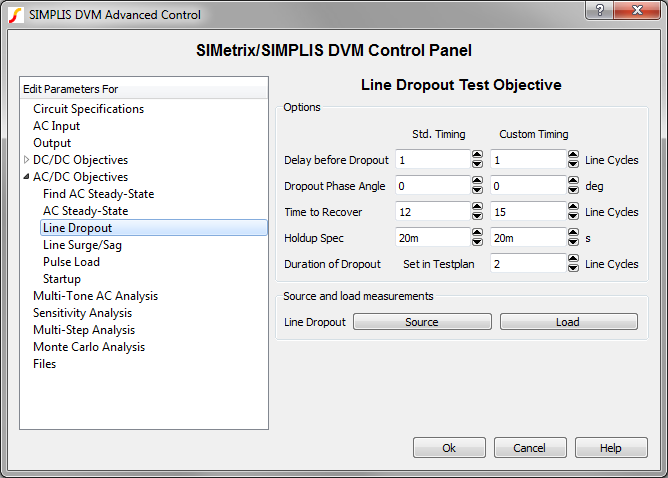

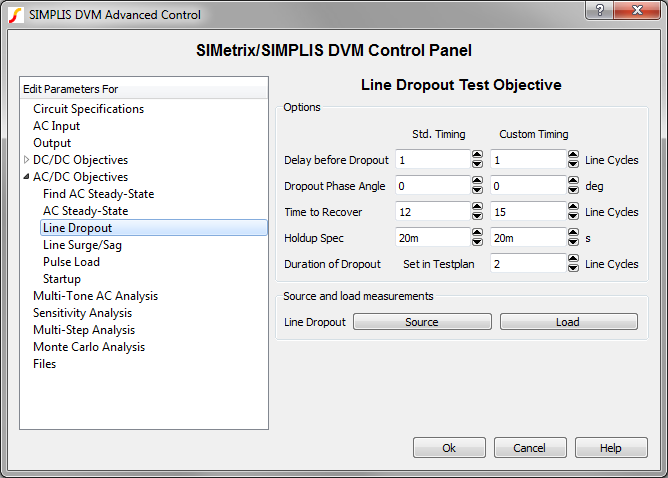

Line Dropout

The Line Dropout Test Objective page allows you to define

parameters for the LineDropout test.

| Standard Timing |

| Delay before

Dropout |

Number of full line cycles

before dropout initiation |

| Dropout Phase Angle |

The phase angle, in

degress, when the line drop out starts |

| Time to Recover |

Number of line cycles to

simulate after the line returns to normal |

| Holdup Spec |

Maximum holdup time

specification for all outputs |

| Custom Timing |

| Delay before

Dropout |

Number of full line cycles

before dropout initiation |

| Dropout Phase Angle |

The phase angle, in

degrees, when the line dropout starts |

| Time to Recover |

Number of line cycles to

simulate after the line returns to normal |

| Holdup Spec |

Maximum holdup time

specification for all outputs |

| Duration of Dropout |

Duration of the dropout in

line cycles |

| Source and load

measurements |

| Line Dropout |

The Source and Load buttons

allow you to select voltage and current measurements for this test

objective. |

▲ back to top

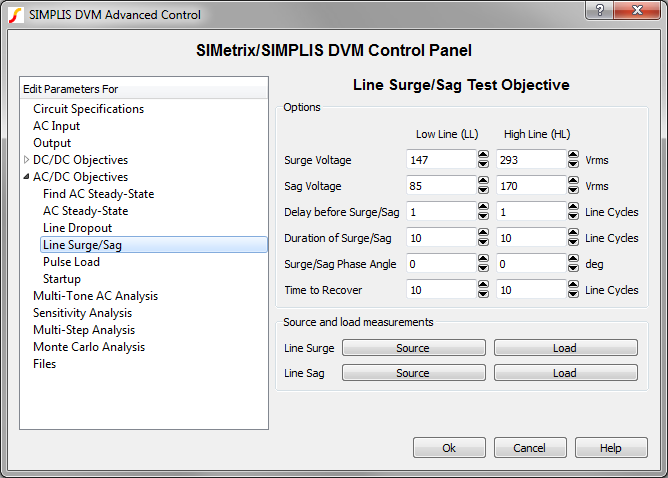

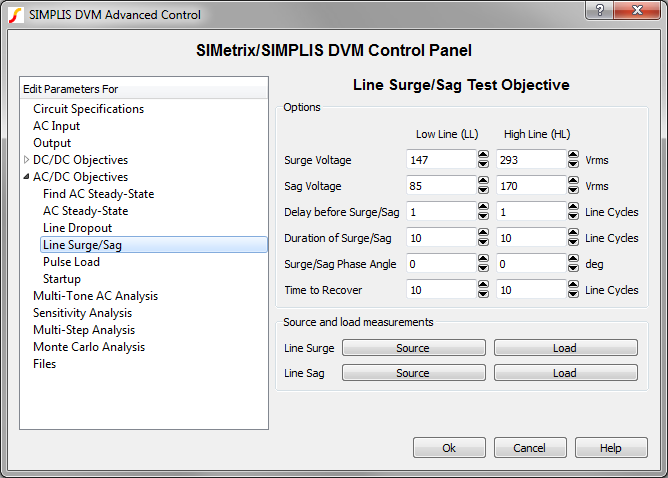

Line Surge/Sag

The Line Surge/Sag Test Objective page allows

you to define parameters for the LineSurge and

LineSag test objectives.

| Options: Low Line (LL) and

High Line (HL) |

| Surge Voltage |

Voltage, in volts RMS, to

which the line surges for LineSurge test objectives |

| Sag Voltage |

Voltage, in volts RMS, to

which the line sags for LineSag test objectives |

| Delay before

Surge/Sag |

Number of full line cycles

to simulate before initiating the line surge or line sag |

| Duration of

Surge/Sag |

Duration, in line cyles, of

surge or sag |

| Surge/Sag Phase

Angle |

The phase angle at which

the line surge or sag is initiated |

| Time to Recover |

Number of line cycles to

simulate after the line returns to normal |

| Source and load

measurements |

| Line Surge |

The Source and Load buttons

allow you to select voltage and current measurements for these test

objectives. |

| Line Sag |

▲ back to top

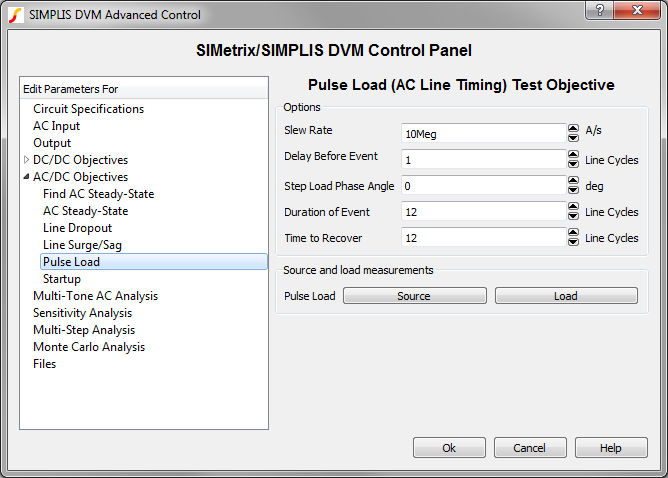

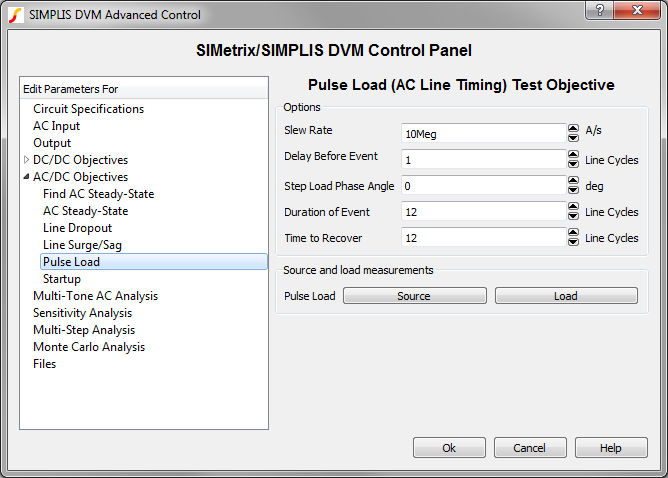

Pulse Load (AC Line Timing)

The Pulse Load (AC Line

Timing) Test Objective page allows you to define the timing parameters for the LoadTrAC Test Objective.

| Options |

| Slew Rate |

Maximum slew rate, in A/s,

at which the load current changes |

| Delay before Event |

Number of full line cycles

to simulate before initiating the load pulse |

| Step Load Phase

Angle |

Line phase angle at which

the load pulse is initiated |

| Duration of Event |

Duration, in line cycles of

the load pulse |

| Time to Recover |

Number of line cycles to

simulate after the load returns to the non-pulse amplitude |

| Source and load

measurements |

| Pulse Load |

The Source and Load buttons

allow you to select voltage and current measurements for this test

objective. |

▲ back to top

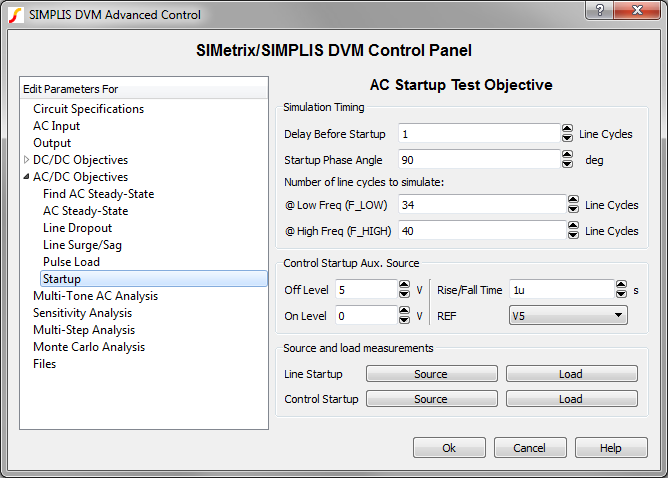

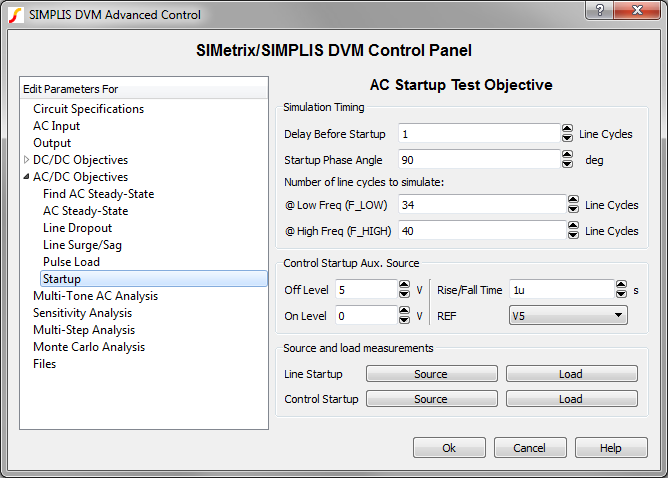

Startup

The AC

Startup Test Objective page allows you to change timing specifications for the LineStartup and ControlStartup test objectives.

| Simulation Timing: |

| Delay Before

Startup |

Number of full line cycles

to delay start up |

| Startup Phase Angle |

Phase angle at which the

line or control startup occurs |

| Number of line cycles to

simulate |

| @Low Freq (F_LOW) |

Number of line cycles to simulate at low frequency. This value is used

to calculate the stop time that is determined by dividing this number

by the F_LOW value specified on the AC Input page. For example, if

this value is 34 and the value on the AC Input page is 50 Hz, the stop

time is 680ms.

|

| @High Freq (F_HIGH) |

Number of line cycles to simulate at high frequency. This value is

used to calculate the stop time that is determined by dividing this

number by the F_HIGH value specified on the AC Input page. For

example, if this value is 40 and the value on the AC Input page is 60

Hz, the stop time is 666.667ms.

|

| Control Startup Aux.

Source |

| Off Level |

The voltage level where the

control input disables the converter |

| On Level |

The voltage level where the

control input enables the converter |

| Rise/Fall Time |

The rise or fall time for

the source |

| REF |

The reference designator

for the control source. The schematic symbol must be a DVM Aux

source. |

| Source and load

measurements |

| Line Startup |

The Source and Load buttons

allow you to select voltage and current measurements for these test

objectives. |

| Control Startup |

▲ back to top

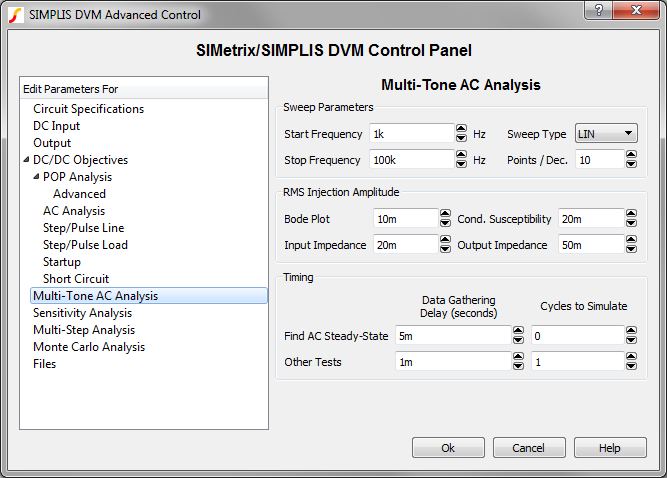

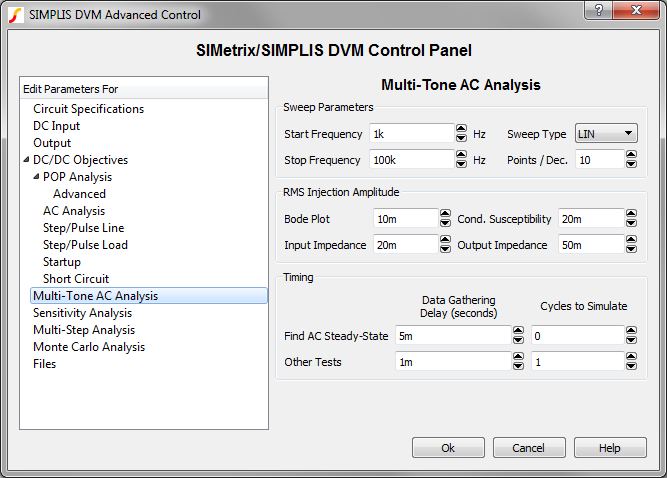

Multi-Tone AC Analysis

The

Multi-Tone AC Analysis page allows you to define parameters for the Multi-Tone AC

Analysis, which is an alternative to the conventional POP/AC Analysis and it does not

require a circuit to have a POP solution. The Multi-Tone AC Analysis is compatible with

both DC/DC and AC/DC converters. Since this is a complicated analysis, you should read

the Multi-Tone AC Analysis - Introduction and the Multi-Tone AC Analysis Theory topics before attempting to apply this analysis to a converter.

| Sweep Parameters |

| Start Frequency |

The lowest injection frequency

for the Multi-Tone Sweep. Because this input also sets the total simulation

time in integer multiples of 1/Start Frequency, you should avoid extremely

low start frequencies. For details, see the Timing table

below. |

| Stop Frequency |

The highest injection

frequency for the Multi-Tone Sweep |

| Sweep Type |

The following sweep types are

available:

-

LIN sets a linear sweep of frequencies starting at the Start

Frequency. This sweep will include every harmonic of the Start

Frequency up to and including the Stop Frequency.

-

DEC approximates a decade sweep between Start Frequency and

Stop Frequency with no more points than the value of Points/Dec.

-

DEC2 applies a combination of the LIN and DEC sweeps: the first

decade consists of linear-spaced frequencies, and subsequent decades

use the DEC method.

All sweeps are limited to

100 frequencies. This limits the LIN sweeps to two decades, whereas the

DEC and DEC2 sweeps can be used for four or more decades. For details,

see Points/Dec. below.

|

| Points/Dec. |

The maximum number of points

for DEC and DEC2 sweeps; not used for LIN sweep types.

As more frequencies are injected, the signal-to-noise ratio in the system

decreases and the AC output waveforms become noisier. Additionally, a high

number of injected frequencies will slow down the simulation considerably.

For this reason, using as few frequencies as possible produces the best

results. |

| Timing |

| Data Gathering Delay: Find AC

Steady-State |

This parameter sets the time

delay before data is generated during Find AC Steady-State tests. The

Data Gathering Delay time needs to be set to allow the circuit to

settle completely into a steady state. For the Fourier analysis to yield

noise-free results, the circuit must be

completely

settled; therefore, set this time delay generously. |

| Data Gathering Delay: Other

Tests |

This parameter sets the time

delay before data is generated for all tests except Find AC Steady-State.

Typically, the initial-conditions file generated from a Find AC Steady-State

test will be extremely close to the circuit's steady state and this delay

can be set to zero. If there is some residual transient, this delay can be

set to allow the circuit to settle before simulation data is

generated. |

| Cycles to Simulate: Find AC

Steady-State |

Find AC Steady-State data will

be collected for this number of Start Frequency cycles after the

Data Gathering Delay. The Find AC Steady-State tests generate an

initial-conditions file. The only reason to make this parameter non-zero is

if you wish to observe the settling behavior of the converter. |

| Cycles to Simulate: Other

Tests |

In conjunction with the

Start Frequency and the Data Gathering Delay: Other Tests,

this parameter determines the simulation stop time:

- Start Frequency

- Data Gathering Delay: Other Tests

- This parameter (Cycles to Simulate: Other Tests)

\[ \text{Simulation Stop Time} = \frac{\text{Cycles to Simulate: Other

Tests}}{\text{Start Frequency}} + \text{Data Gathering Delay: Other Tests}

\] The simulation time span

is then determined as follows:

\[ \text{Simulation Time Span} =

\frac{\text{Cycles to Simulate: Other Tests}}{\text{Start Frequency}} \] For example, if the

Cycles to Simulate is 2 and the Start Frequency is 1kHz,

the simulation will have 2ms of simulated data. The Simulation Time Span

will always be an integer multiple of the lowest period: \[

\frac{\text{1}}{\text{Start Frequency}} \]

|

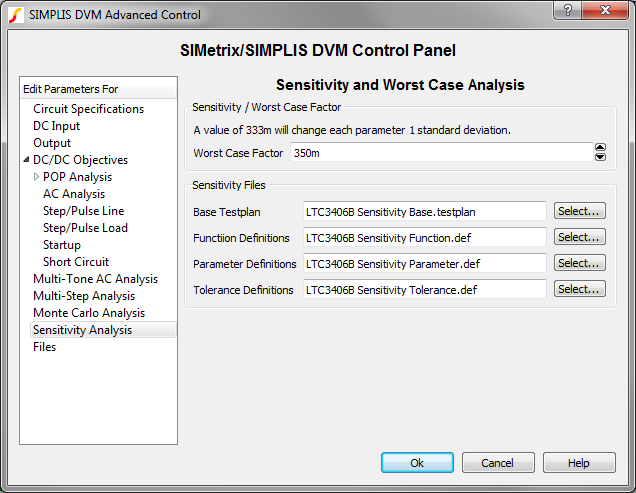

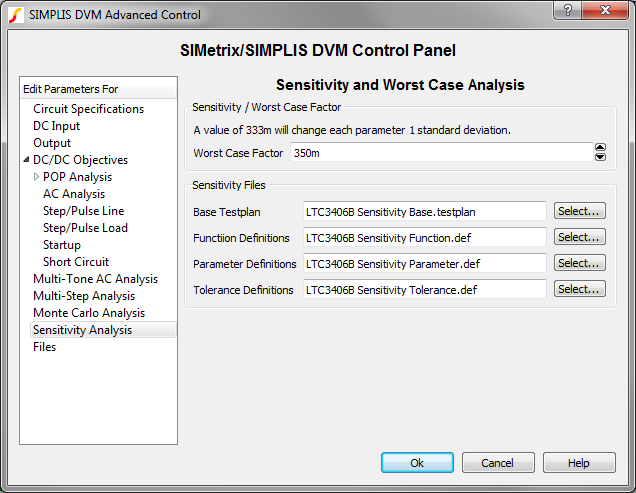

Sensitivity/Worst-Case

Analysis

Sensitivity and

Worst-Case Analysis is a special analysis used to evaluate the effect of parameter

variation on converter performance. The analysis is described in detail in the DVM Sensitivity and Worst-Case Analysis topic. The

dialog is described below.

| Sensitivity / Worst Case

Factor |

| Worst Case Factor |

During sensitivity analysis,

each design parameter is increased by an amount equal to the worst-case

factor multiplied by the user-defined tolerance. A value of 333m represents

a change of one standard deviation in the positive direction. |

| Sensitivity Files |

| Base Testplan |

Select the sensitivity base

testplan for this schematic. This is the tesplan is used for sensitivity and

worst-case analyses. |

| Function Definitions |

Select the function definition

file for the sensitivity analysis. |

| Parameter Definitions |

Select the parameter

definition file for the sensitivity analysis. |

| Tolerance Definitions |

Select the tolerance

definition file for the sensitivity analysis. |

▲ back to top

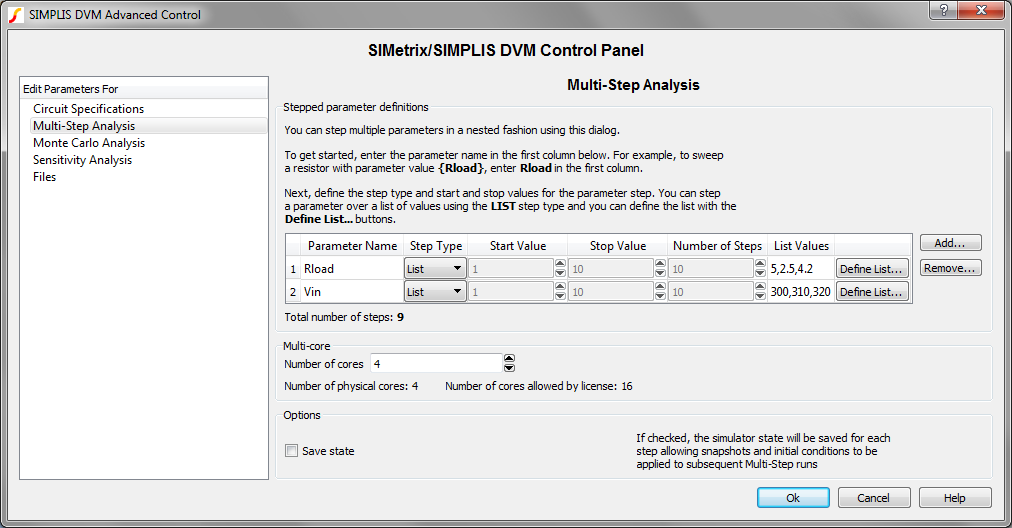

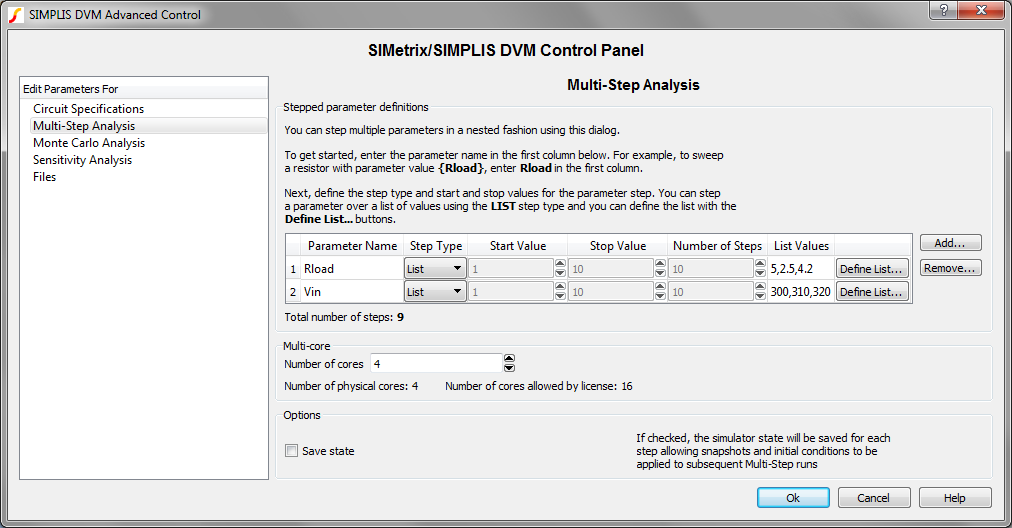

Multi-Step Analysis

The DVM Multi-Step Analysis allows you to step a set of design

parameters over a range of values using a decade-step or linear-step sequence. You may also

step values over a defined list of parameter values. One advantage of using a single test

with a multi-step analysis over multiple DVM tests is the multi-core capability which is

part of the Pro and Elite license packages. The multi-core capability runs steps in

parallel on multiple processor cores and will greatly reduce the simulation time required

for the multi-step analysis. Even using a single processor core reduces the required

simulation time as the schematic is setup once, as is the graph and data collection after

the simulation completes.

For more information, see the Multi-Step Analysis topic.

The table on the Multi-Step Analysis page allows you to enter the parameter names and

their associated step parameters. The dialog allows you to configure three different

step modes:

- A Linear step where the parameter is stepped from the Start Value

to the Stop Value using the Number of Steps in a linearlly spaced

sequence. The number of steps run will always be the parameter entered into the

Number of Steps field.

- A Decade step where the parameter is stepped from the Start Value

to the Stop Value using the Number of Steps

per decade in a logarithmic sequence. The total number of steps depends on

the Start Value, Stop Value, and the Number of Steps.

- A List sequence where the parameter is stepped over a user-defined list of

parameter values. There are no restrictions on the values of the list. The total

number of steps depends only on the number of values entered.

To enter parameter step information, follow these steps:

- Enter a parameter name in the Parameter Name column.

- Select the desired Step Type from the drop-down list. After you select the

step type, the rest of the valid controls for this parameter are enabled.

- For List step types, enter the list of values by double clicking on the

List Values table cell or click on the Define List...

button.

| Table Column |

Description |

| Parameter Name |

The name of the stepped

parameter. The schematic symbols should be parameterized with this

parameter name using braced {} substitutions as shown at the top of the

dialog image above. Note: You can automatically change symbol property

values by using the Change testplan entry.

|

| Step Type |

The step type can be one of

the following:

-

Decade: The stepped parameter is stepped

logarithmically.

-

Linear: The stepped parameter is stepped in a linear

fashion.

-

List:The parameter is stepped over a list of values. To

define the list, click the Define List... button.

|

| Start Value |

The starting value for the

parameter step, used with decade and linear steps |

| Stop Value |

The ending value for the

parameter step, used with decade and linear steps |

| Number of Steps |

The number of steps for the

decade or linear steps. For decade steps, this parameter value is the

number of steps per decade, for linear steps, the parameter value is the

number of equally spaced steps. |

| List Values |

The list of stepped values.

This cell is automatically populated by the dialog opened with the

Define List... button. |

Additional parameters can be stepped by clicking on the Add... button

and individual parameters can be removed with the Remove... button. The total

number of steps is the product of number of steps for each stepped parameter. The

total number of steps is calculated and shown below the table in the Total number

of steps text.

Note: Parameters in the table with an empty parameter name

are not saved when you accept the dialog.

| Multi-core |

| Number of cores |

The number of cores used

for the simulation. The Pro and Elite licenses allow the use of 4 and 16

cores respectively. |

| Save state |

If checked, SIMPLIS will save initial

conditions files with names which reflect the stepped parameter values.

You can use the GenerateInitFile

entry to save the initial conditions files and the IncludeInitFile entry to include

these files. |

▲ back to top

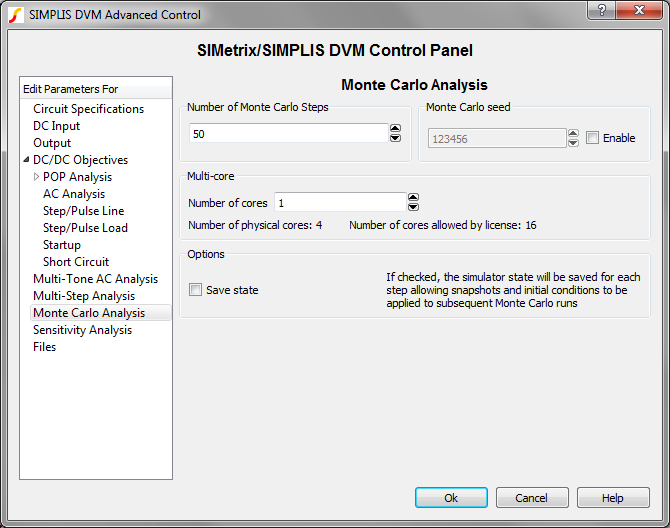

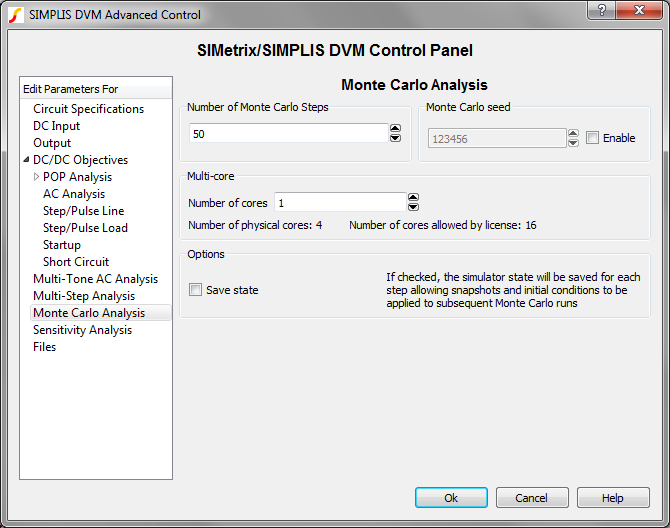

Monte Carlo Analysis

The Monte Carlo analysis allows you to investigate the effect of

random parameter value changes on your circuit. The Monte Carlo analysis assumes that you

have set up your circuit with statistical parameter distribution functions.

For more information, see the Monte Carlo Analysis topic.

| Parameters |

| Number of Monte Carlo

Steps |

The number of steps, or

simulations, to run |

| Monte Carlo Seed |

The seed value for the Monte

Carlo simulation. The seed value starts the pseudo-random number generator

at a specific value. Subsequent seeds follow a predictable pattern, which

makes the Monte Carlo simulation repeatable. |

| Multi-core |

| Number of cores |

The number of cores used for

the simulation. The Pro and Elite licenses allow the use of 4 and 16 cores

respectively. |

| Save state |

If checked, SIMPLIS will save initial

conditions files with names which match the Monte Carlo seed values. You can

use the GenerateInitFile entry to

save the initial conditions files and the IncludeInitFile entry to include these

files. Important: You must enable and provide a starting seed

to include the initial conditions files.

|

▲ back to top

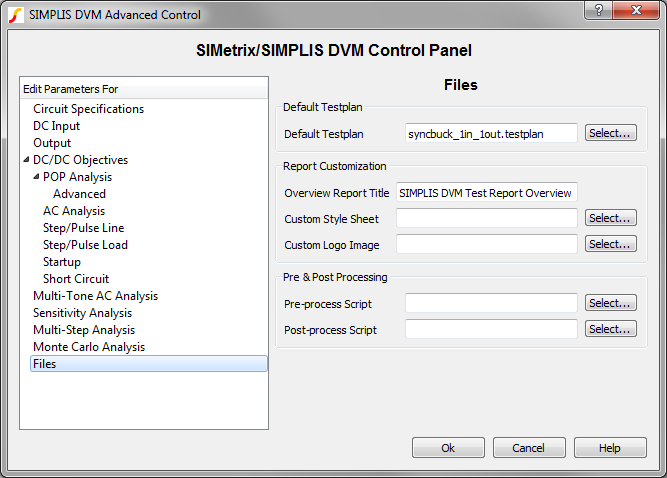

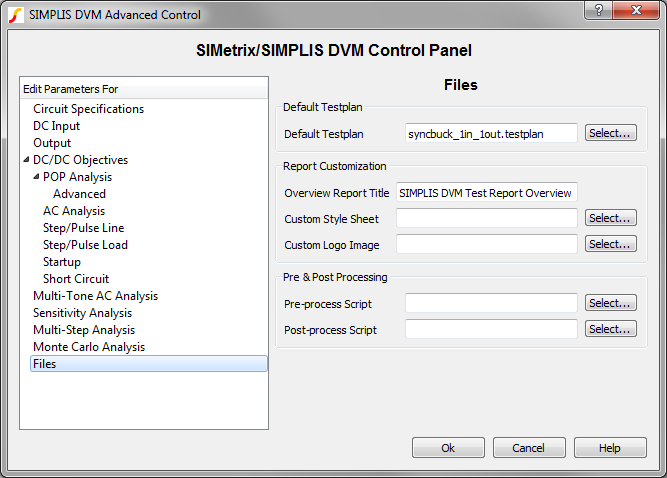

Files Page

The Files page allows you to do the following:

- Assign a default testplan

- Customize the appearance of the simulation reports

- Add Pre-process and Post-process

scripts to be run on every simulation

| Default Testplan: used

when you select either DVM ▶ Run Schematic's Default Testplan or DVM ▶

Run Entire Schematic's Default Testplan from the menu bar. |

| Default Testplan |

Specifies the default

testplan to be used with this schematic. |

| Report Customization:

Options to customize the appearance of the DVM report |

| Overview Report

Title |

The title used on the

overview report. The titles for individual test reports can be changed

with the HTMLTitle testplan

entry. |

| Custom Style Sheet |

Cascading Style Sheet (CSS

file) to use with the DVM report |

| Custom Logo Image |

Portable Network Graphics

(PNG) file to use with the DVM report |

| Pre & Post

Processing |

| Pre-process Script |

SIMetrix script to be

executed immediately before launching each simulation; this allows you to

change schematic values or analysis statements before running the test.

Preprocess scripts are executed after all Objective entries are

processed which allows users to override any schematic changes made by

DVM. |

| Post-process Script |

SIMetrix script to be

executed immediately after each simulation successfully completes; this

allows you to perform waveform manipulation and to create custom scalar

and specification values. |

▲ back to top